Coating

Coating Advantages

Coating Advantages

- Protect and add to the lifespan of your Investments

- Keep it looking pristine

- Reduce maintenance time & costs

- Increase in profit margins

- Self-Cleaning assets

- Environmentally Sustainable Design (ESD)

- Protection from Co2, Corrosion, Water, Frost …

- Anti-Graffiti, Anti-Carbonation

- Protection of Street arts.

- UV protection

Fusion technology coatings allow our products to be unique and cost competitive.

They do not stop at improving the surface properties but optimize them for increase performances and durability. The fusion technology ensures a fusion-like connection on a molecular level between the coating and the base. Similar chemical structures are created within the coating that are already present in the base material that is to be coated.

The key to the permanent stability of a coated surface lies both in the durability of the coating itself and in its optimum connection with the material to be coated. The decisive advantage of the fusion technology lies in the optimization of both components.

Coating New Technology

Coating New Technology

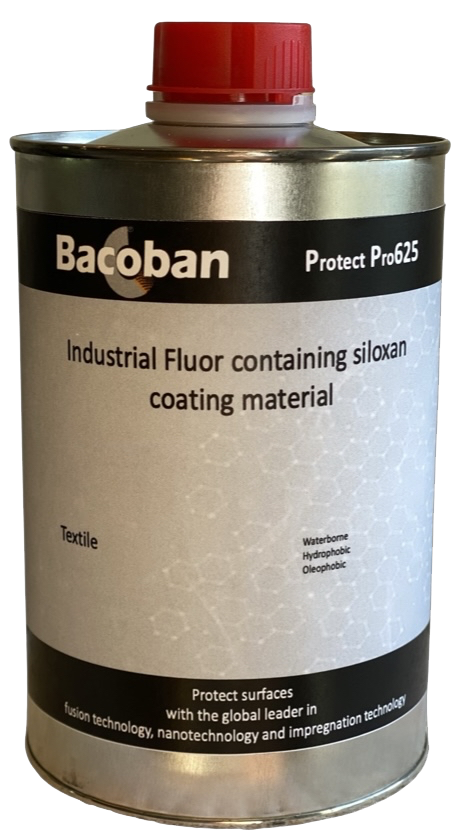

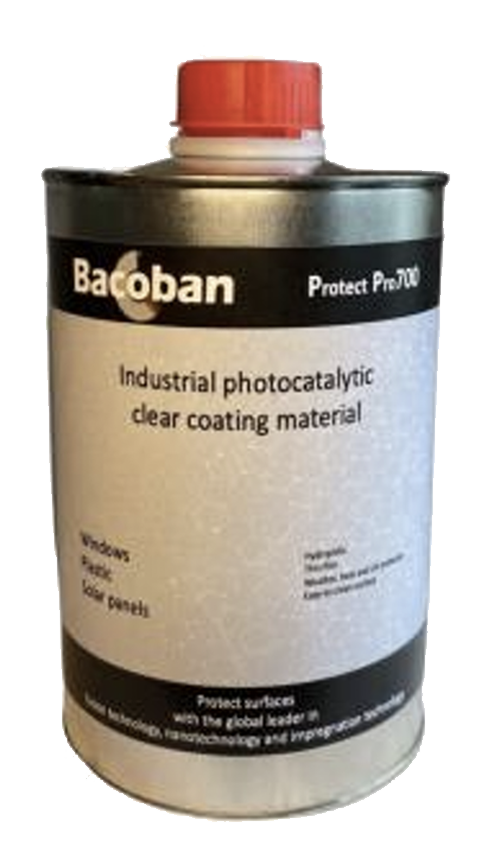

Bacoban’s product offer nanotechnology coatings capable of modifying the surface to provide them with advanced features.

Conventional epoxy coatings for example, provide remarkable adhesion and great initial protection against dirt, corrosion resistance, abrasion and chemical resistance. These epoxy based coated assets begin to fall short when exposed to harsh UV rays and long-term environmental attack. When these painted assets begin to degrade or chalk from the sun, corrosion resistance and other physical properties become ’’adversely impacted’’.

Bacoban’s nanotechnology coatings creates a seamless bond that is impenetrable by liquids and will protect the surface from dirt, corrosion, UV rays, bacteria, viruses, fungi and decay.

The basis of all Bacoban coatings is the evolution from organic materials (paint, epoxy etc.) to inorganic materials (Sol-Gel or nanotechnology). Our technology have gone further by creating coatings that have similarities with the surfaces to be coated « The Fusion Technology ». Our coatings provide a chemical connection, or fusion between the coated surface and the coating; a permanent protection. Bacoban coatings were designed to be applied directly on the surface or over epoxy and PU based coatings to combat severe environmental conditions and dramatically improve the corrosion resistance, abrasion, chemical & UV resistance of painted assets.

The substrate and our coating undergo a covalent chemical connection: the fusion between the substrate and the coating on a molecular level to form an inorganic polymer network. Our coatings also have organic chains to set the surface properties compatibility. The fusion technology provides for easier application steps. The surfaces to be coated need only be free of dust, grease and oil. Of course, the first step will be to remove the coarse material and repair the cracks.